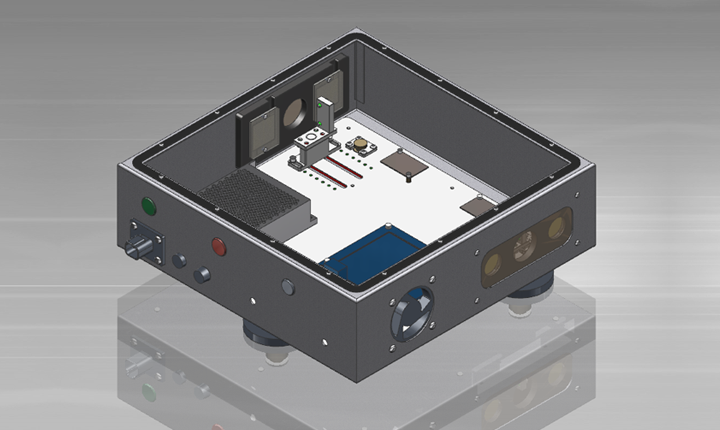

CAD

Our company offers a wide range of services apart from the strictly machining ones. Computer Aided Design (CAD) services can be offered in order to facilitate the transition from a mere inspiration into a component fully dimensioned and ready to be produced, by creating the 3D models accompanied by the detailed mechanical drawings. This procedure is performed through the Siemens NX modeling and evaluation software which is the main software tool of this company. In this context, a multitude of functionalities can be met, including exhibition purposes, highly realistic renderings and animations and more importantly motion analysis and evaluation of even the most complex kinematic mechanisms.

The same applies in mold design and machining. Creating molds able to produce components of various shapes and sizes, requires the detailed 3D representation of the component at hand which is in turn used to create the proper mold.

The same applies in mold design and machining. Creating molds able to produce components of various shapes and sizes, requires the detailed 3D representation of the component at hand which is in turn used to create the proper mold.

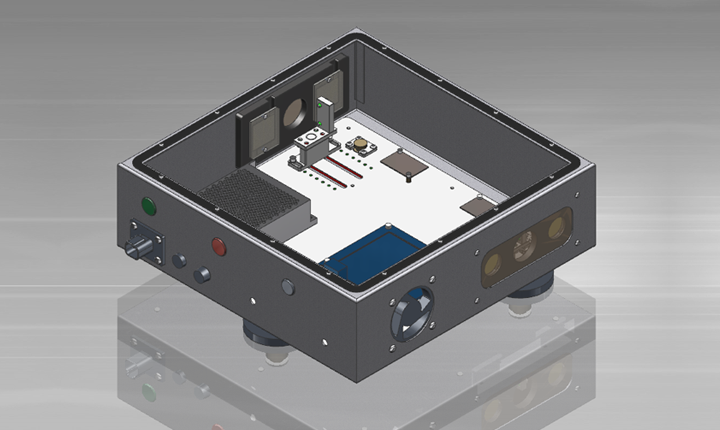

CAD

Our company offers a wide range of services apart from the strictly machining ones. Computer Aided Design (CAD) services can be offered in order to facilitate the transition from a mere inspiration into a component fully dimensioned and ready to be produced, by creating the 3D models accompanied by the detailed mechanical drawings. This procedure is performed through the Siemens NX modeling and evaluation software which is the main software tool of this company. In this context, a multitude of functionalities can be met, including exhibition purposes, highly realistic renderings and animations and more importantly motion analysis and evaluation of even the most complex kinematic mechanisms.

The same applies in mold design and machining. Creating molds able to produce components of various shapes and sizes, requires the detailed 3D representation of the component at hand which is in turn used to create the proper mold.

The same applies in mold design and machining. Creating molds able to produce components of various shapes and sizes, requires the detailed 3D representation of the component at hand which is in turn used to create the proper mold.

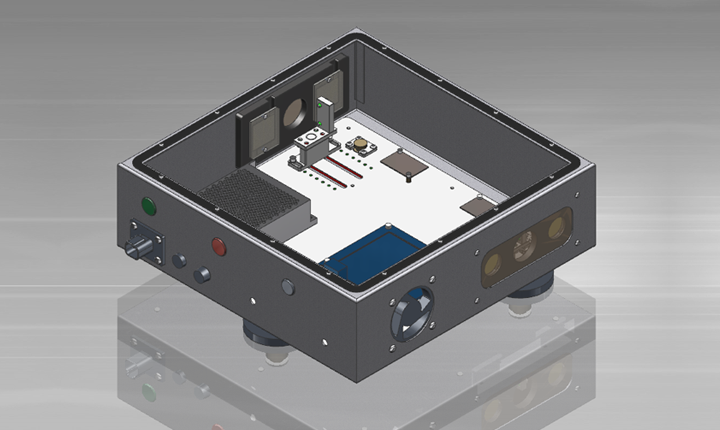

CAD

Our company offers a wide range of services apart from the strictly machining ones. Computer Aided Design (CAD) services can be offered in order to facilitate the transition from a mere inspiration into a component fully dimensioned and ready to be produced, by creating the 3D models accompanied by the detailed mechanical drawings. This procedure is performed through the Siemens NX modeling and evaluation software which is the main software tool of this company. In this context, a multitude of functionalities can be met, including exhibition purposes, highly realistic renderings and animations and more importantly motion analysis and evaluation of even the most complex kinematic mechanisms.

The same applies in mold design and machining. Creating molds able to produce components of various shapes and sizes, requires the detailed 3D representation of the component at hand which is in turn used to create the proper mold.

The same applies in mold design and machining. Creating molds able to produce components of various shapes and sizes, requires the detailed 3D representation of the component at hand which is in turn used to create the proper mold.

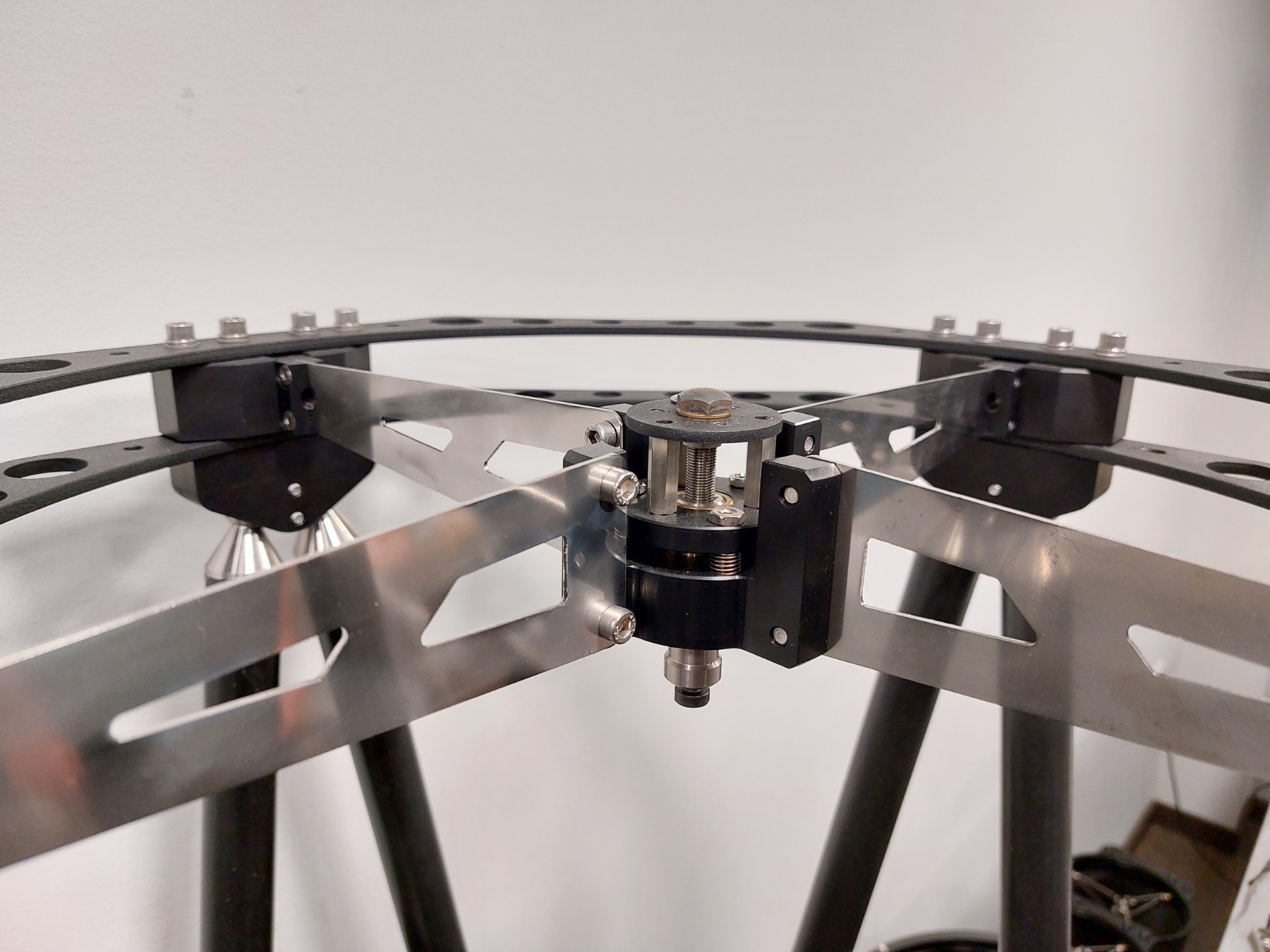

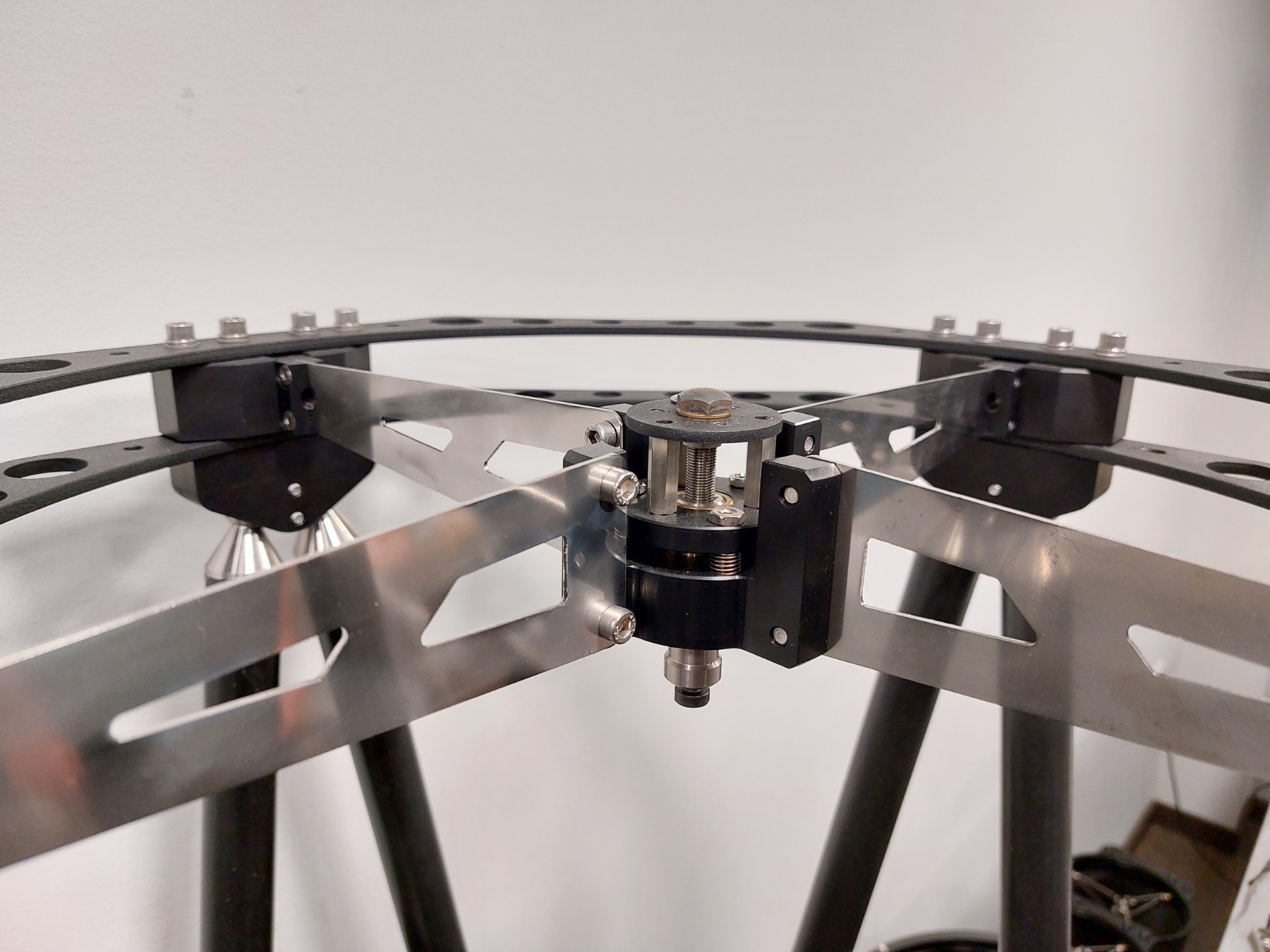

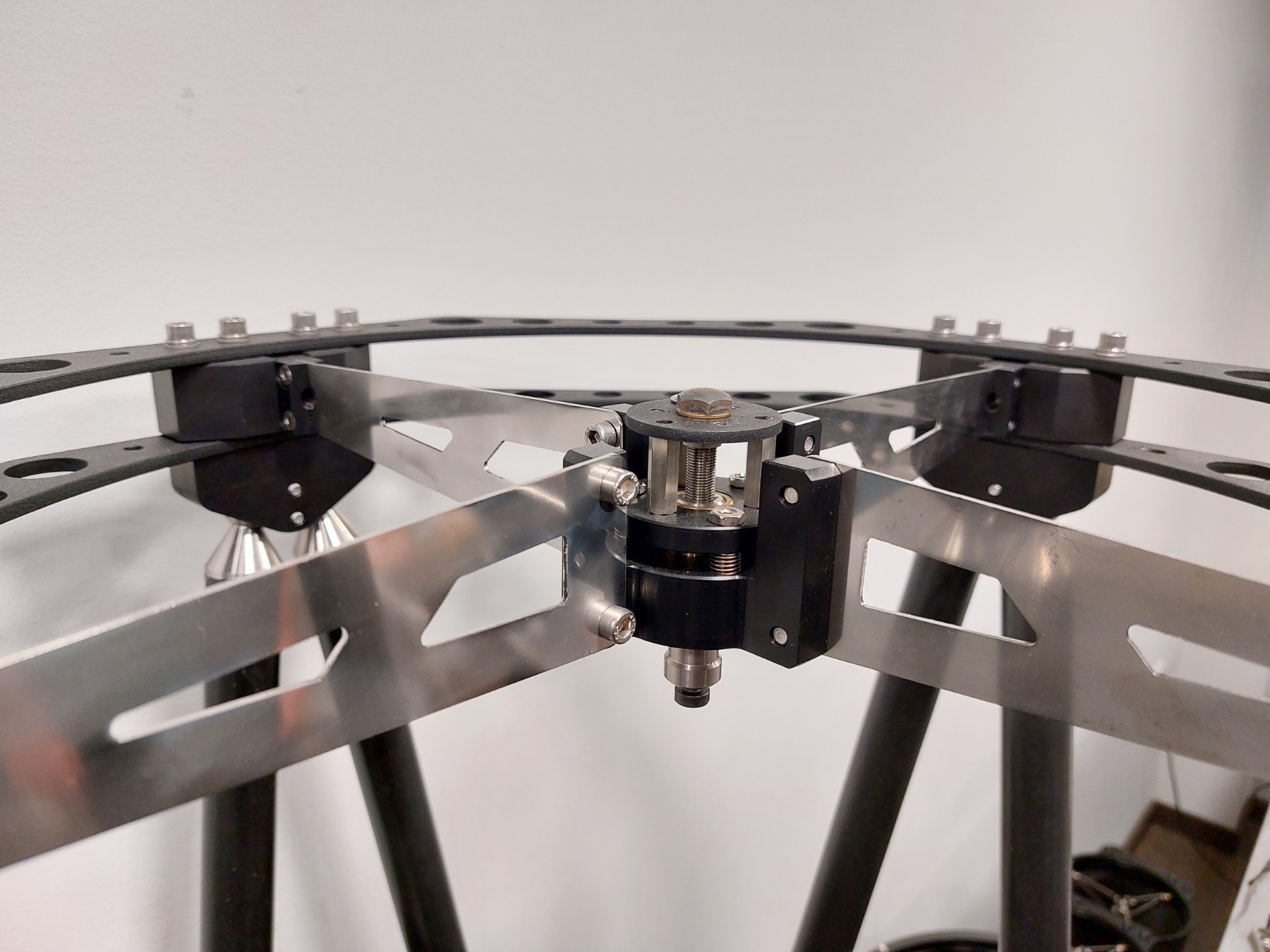

CUSTOM SOLUTIONS

The customer’s vision can be developed from scratch and turned into a final product. We give emphasis to innovation, cost efficiency and most importantly in the application of basic mechanics which ensure the proper functionality of the final product from the early stages of its development. Advisory services can also be provided throughout the whole process of development.

Aiming at the highest levels of our customers’ satisfaction, the principles of Design for Manufacture (DFM) and Design for Assembly (DFA) as well as maintenance, low cost and life cycle performance are taken into account during the design process. Whenever the need has risen, tailor made jigs and fixtures have been designed in order to provide repeatability and accuracy in the machining process. Our overall primitives are quality insurance and time efficient machining.

For the reassurance and the visualization of the products designed we also develop and provide 3D prototypes giving the opportunity to the customer to detect features that they want to be added, removed or generally changed as well as functionalities.

Aiming at the highest levels of our customers’ satisfaction, the principles of Design for Manufacture (DFM) and Design for Assembly (DFA) as well as maintenance, low cost and life cycle performance are taken into account during the design process. Whenever the need has risen, tailor made jigs and fixtures have been designed in order to provide repeatability and accuracy in the machining process. Our overall primitives are quality insurance and time efficient machining.

For the reassurance and the visualization of the products designed we also develop and provide 3D prototypes giving the opportunity to the customer to detect features that they want to be added, removed or generally changed as well as functionalities.

The customer’s vision can be developed from scratch and turned into a final product. We give emphasis to innovation, cost efficiency and most importantly in the application of basic mechanics which ensure the proper functionality of the final product from the early stages of its development. Advisory services can also be provided throughout the whole process of development.

Aiming at the highest levels of our customers’ satisfaction, the principles of Design for Manufacture (DFM) and Design for Assembly (DFA) as well as maintenance, low cost and life cycle performance are taken into account during the design process. Whenever the need has risen, tailor made jigs and fixtures have been designed in order to provide repeatability and accuracy in the machining process. Our overall primitives are quality insurance and time efficient machining.

For the reassurance and the visualization of the products designed we also develop and provide 3D prototypes giving the opportunity to the customer to detect features that they want to be added, removed or generally changed as well as functionalities.

Aiming at the highest levels of our customers’ satisfaction, the principles of Design for Manufacture (DFM) and Design for Assembly (DFA) as well as maintenance, low cost and life cycle performance are taken into account during the design process. Whenever the need has risen, tailor made jigs and fixtures have been designed in order to provide repeatability and accuracy in the machining process. Our overall primitives are quality insurance and time efficient machining.

For the reassurance and the visualization of the products designed we also develop and provide 3D prototypes giving the opportunity to the customer to detect features that they want to be added, removed or generally changed as well as functionalities.

CUSTOM SOLUTIONS

The customer’s vision can be developed from scratch and turned into a final product. We give emphasis to innovation, cost efficiency and most importantly in the application of basic mechanics which ensure the proper functionality of the final product from the early stages of its development. Advisory services can also be provided throughout the whole process of development.

Aiming at the highest levels of our customers’ satisfaction, the principles of Design for Manufacture (DFM) and Design for Assembly (DFA) as well as maintenance, low cost and life cycle performance are taken into account during the design process. Whenever the need has risen, tailor made jigs and fixtures have been designed in order to provide repeatability and accuracy in the machining process. Our overall primitives are quality insurance and time efficient machining.

For the reassurance and the visualization of the products designed we also develop and provide 3D prototypes giving the opportunity to the customer to detect features that they want to be added, removed or generally changed as well as functionalities.

Aiming at the highest levels of our customers’ satisfaction, the principles of Design for Manufacture (DFM) and Design for Assembly (DFA) as well as maintenance, low cost and life cycle performance are taken into account during the design process. Whenever the need has risen, tailor made jigs and fixtures have been designed in order to provide repeatability and accuracy in the machining process. Our overall primitives are quality insurance and time efficient machining.

For the reassurance and the visualization of the products designed we also develop and provide 3D prototypes giving the opportunity to the customer to detect features that they want to be added, removed or generally changed as well as functionalities.